- Main Number

(855) 667-3655 - Emergencies

(800) 453-2530 - Crossing gates, signals & rough crossings

(800) 453-2530 - Environmental Spills

(800) 453-2530

Introducing the Wheel Integrity System: NS’ latest safety revolution

By Chad Previch, Senior Communications Manager

The system is now live near Chicago; more sites planned for 2026

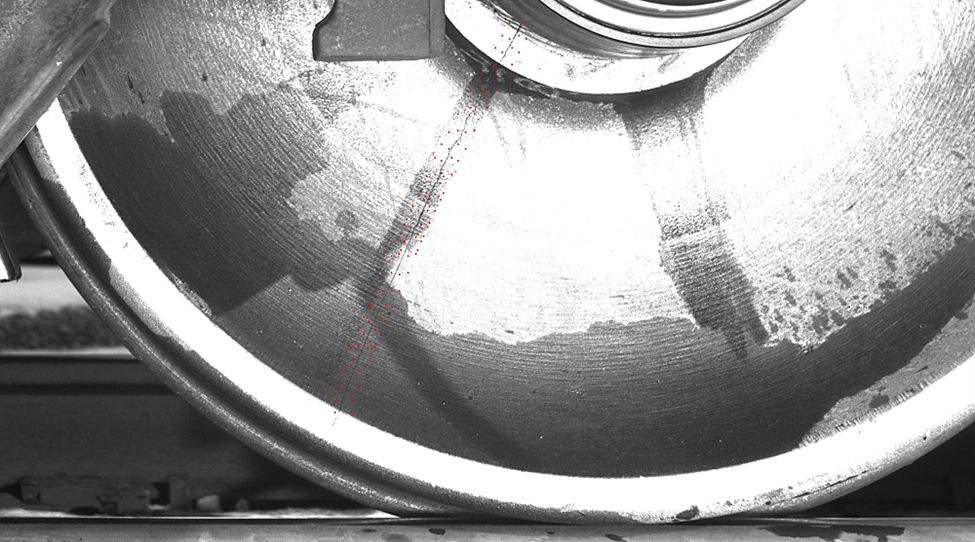

Norfolk Southern has combined AI with hands-on railroad expertise to create a cutting-edge wheel integrity system designed to catch defects before they become larger issues. The first system went live Nov. 24 at Burns Harbor, Ind., a strategic site near Chicago for freight transport. This location allows NS to inspect cars entering and leaving its network, providing safety benefits for NS and the industry as a whole.

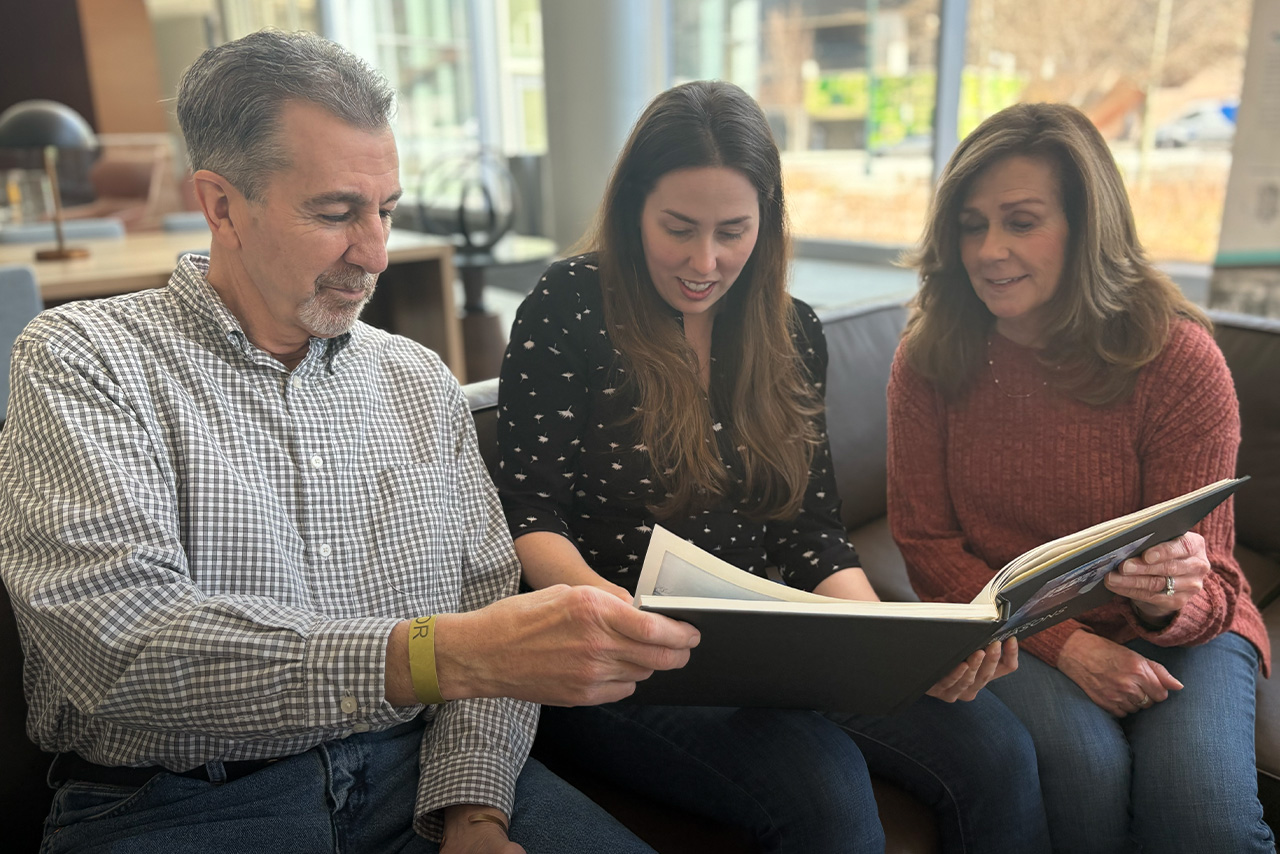

The Burns Harbor wheel integrity system detected a cracked wheel that was confirmed by NS teams. The associated car was removed from service before a larger problem emerged.

Why it matters: Wheel defects are among the most serious mechanical defects in the industry. The technology allows our railroaders to address maintenance needs promptly, enhancing safety, reducing service disruptions and protecting long-term asset performance.

Big results already: The new wheel integrity system pinpointed a critical external vendor casting flaw on a wheel set. Coupled with our relentless root cause investigation, the technology initiated an industry recall and the confirmation of seven confirmed defects across North America.

Zoom out: The new standalone system was built upon the success of the existing Digital Train Inspection (DTI) portals, which have already identified and removed from service over 50 wheels with issues since January 2025. With algorithms developed entirely by NS, the wheel integrity system is the first for the railroad industry. Unlike the NS DTI portals, which scan entire trains, the new system zeroes in on wheels, capturing ultra-high-resolution images from critical angles to identify cracks.

How it works: Six synchronized cameras capture about 55 high-resolution images per wheel at speeds up to 70 mph. The AI algorithms, developed by NS’ in-house Data Science/AI Team, analyze images to detect subtle defects difficult for the human eye to identify consistently. Collaboration across multiple teams, including Operations and Digital & Technology, with integration support from Georgia Tech Research Institute, brought the breakthrough technology to life.

What we’re saying:

“This is a railroad-designed solution for a railroad problem. We’re the first to deploy a vision-based system that identifies cracks before they break, and we did it with our own technology and talent.” — Brian Yeager, Senior Director of Mechanical Operations & Support.

What’s next: NS plans to expand the wheel integrity system in 2026.

Chad Previch leads external communications for Norfolk Southern in the areas of Sustainability, Community Impact and Technology. He also manages messaging related to the company’s Government Relations and Investor Relations priorities. He joined NS in 2025, bringing nearly 20 years of PR and corporate communications experience.

Media Contacts

Are you a member of the media? Contact our media relations team.